Skalar is established in 1965 as a producer of analyzers for the laboratory and process industry

and since then grown into a multinational organization. With subsidiaries in most European countries, North America and India and with over eighty representatives throughout the world. Our organization is daily focused on servicing and providing the best application support to existing and potential users.

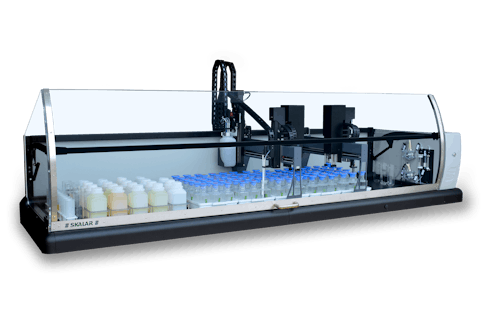

Let's team up!Trace level nutrient analysis in environmental samples with BLUVISION®

Why did Skalar develop a discrete analyzer specifically for the environmental sector?

Want to know more? Watch this pre-recorded webinar session on-demand. Contact us to receive the link.

For your chemistry automation!

Yes we have a lot to offer!

We're here to help!

Skalar uses the highest quality parts and materials, because we know how important it is to keep your analyzer running in an optimal condition. We are aware that in some cases assistence is needed. Our team of professionals will then be ready for you.

Support +31 76 548 6486You want to receive information about events, webinars and the latest (product) news?

Subscribe to our newsletter and don't miss any Skalar news.